Blog

PSS Successfully Re-Engineers and Restores Sea Water Pump Impeller at a Power Plant in the Philippines

In March 2025, one of the six installed circulating water pump units at a power plant in the Philippines tripped due to high vibration. Subsequent inspection revealed a catastrophic impeller vane failure on a 5-vane vertical mixed-flow pump supplied by the OEM. The pump handles 16,900 m³/hr of seawater at 700 rpm, with no redundancy. This failure resulted in a significant energy generation loss.

Root Cause Analysis:

Our Engineering Team at PSS conducted a detailed and methodical Root Cause Analysis (RCA) to identify the true origin of the failure. The process included:

Reviewing DCS motor vibration data and pump operating logs.

Disassembling the pump and inspecting all internal components, where one vane was found completely broken and another showed major cavitation damage.

Carefully examining the pump suction chamber, which confirmed that vortex breakers were installed correctly and there were no signs of vortex formation.

Confirming that the traveling inlet screens were functional and not blocked.

Ensuring that no foreign objects or debris were present in the pump sump to rule out foreign object damage (FOD).

Verifying that inlet water levels during operation provided sufficient NPSHa to eliminate insufficient NPSH as a root cause.

Following elimination of all these potential contributors, our team turned to the impeller geometry. 3D laser scanning and CAD analysis of the failed impeller showed:

Severe cavitation damage localized on two of the five impeller vanes, including the fractured one and an adjacent vane.

The unique and uncommon cavitation pattern was traced to vane geometry inconsistencies likely due to multi-section casting and aggressive hand grinding.

Non-uniform vane mass and volume led to uneven flow patterns and localized pressure drops, contributing to high cavitation erosion.

These flow disruptions created micro-implosions that eroded the metal over time and eventually caused vane fracture.

Engineering and Repair Approach:

This was an emergency repair to restore pump operation while PSS completes manufacturing of a new re-engineered precision investment cast impeller for future installation.

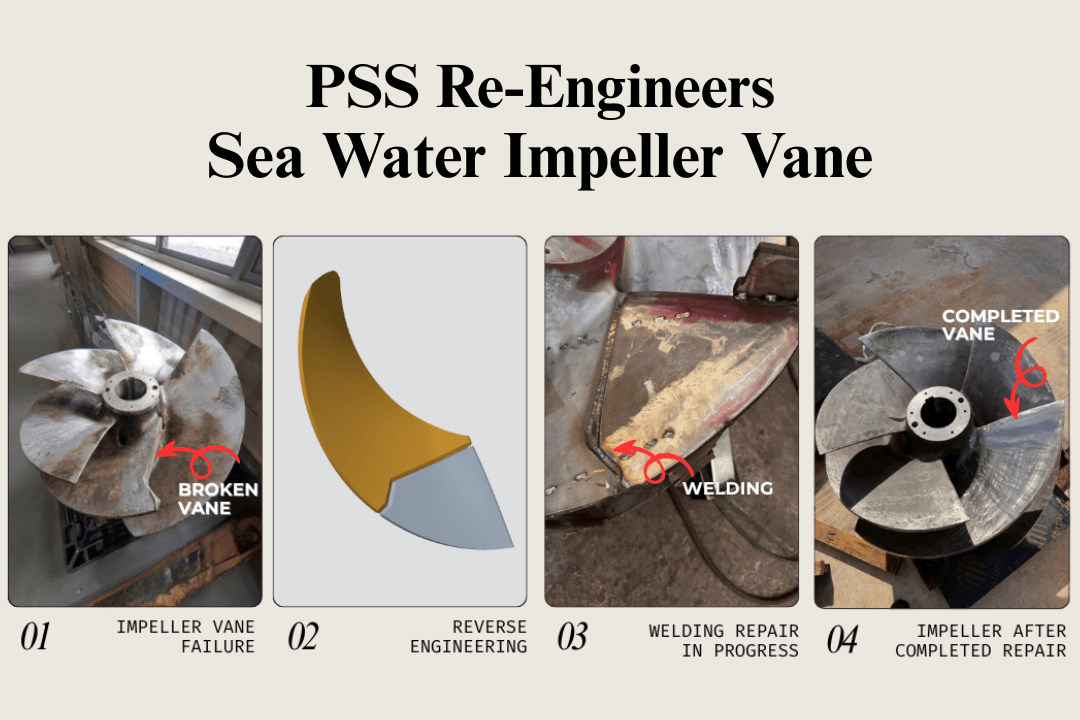

Step 1 – Failure Inspection:

One vane was found to be completely broken. Another vane showed significant cavitation damage. No major damage from domestic object impact was found on the remaining vanes.

Step 2 – Reverse Engineering:

Using 3D scanning and CAD modeling, our team recreated the original vane profile with accurate curvature and flow passage geometry.

Step 3 – Precision Weld Build-Up:

The broken vane section was rebuilt using our 3D model as reference to restore the original geometry with high accuracy. A custom weld repair was performed on-site using super duplex filler compatible with the original impeller material. As the required TIG welding wire was not available locally, PSS urgently hand-delivered the material to site. Our technicians shaped the weld buildup using the digital model, ensuring the restored vane matched the original vane profile. This eliminated distortion and enabled efficient flow restoration.

Step 4 – Final Machining and Balancing:

Dynamic balancing was conducted to eliminate vibration. The repaired impeller passed PSS’s strict QA/QC validation checks.

Result:

Impeller successfully re-installed.

The pump has been returned to service.

The client avoided extended downtime and maintained operational continuity until the new impeller is ready.

Conclusion:

This project demonstrates PSS’s unique capability to respond to emergency failures, reverse engineer damaged components, and restore large critical rotating equipment. Our in-house 3D scanning, modeling, and welding repair capabilities enabled a fast turnaround and ensured temporary but reliable performance. A precision investment cast impeller is under production for long-term solution implementation.

Trust PSS for your rotating equipment challenges.

Contact us to learn more about our impeller repair and upgrade services.