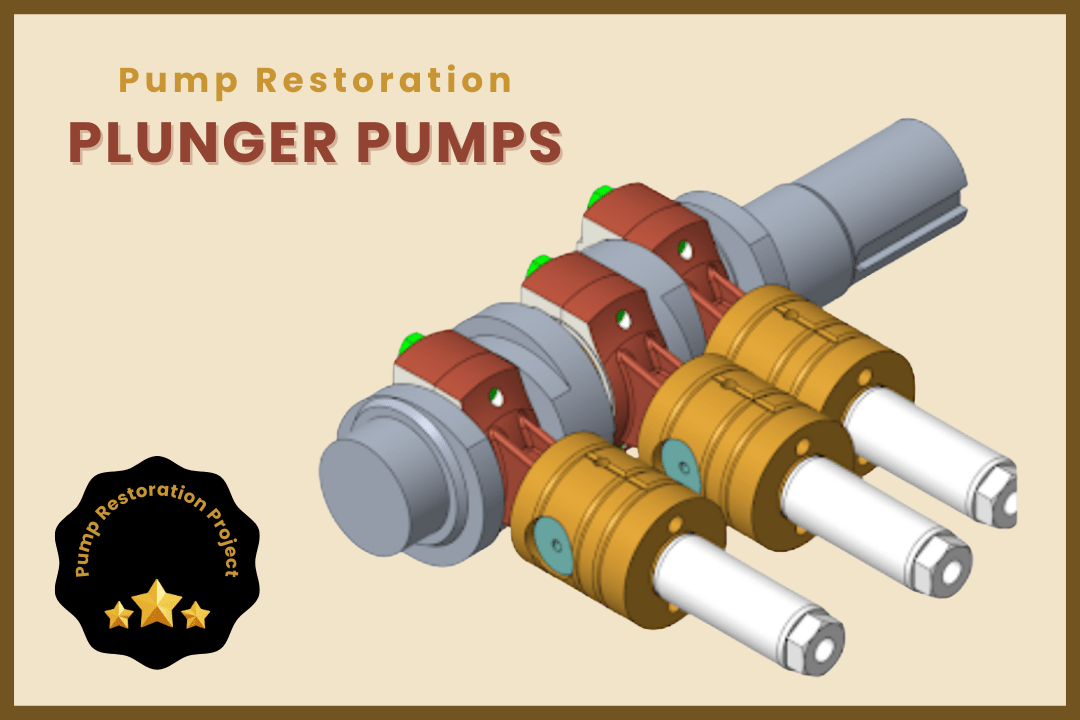

PSS Restores Plunger Pumps for Crude Oil Extraction

PSS recently completed a total restoration of a plunger pump supplied by a customer in the oil drilling industry. Plunger pumps are essential in crude oil extraction, especially in onshore and offshore drilling. These pumps handle high-pressure fluids, inject fluids into wells, and circulate drilling muds, which puts immense stress on their components. The pump was completely worn out, […]

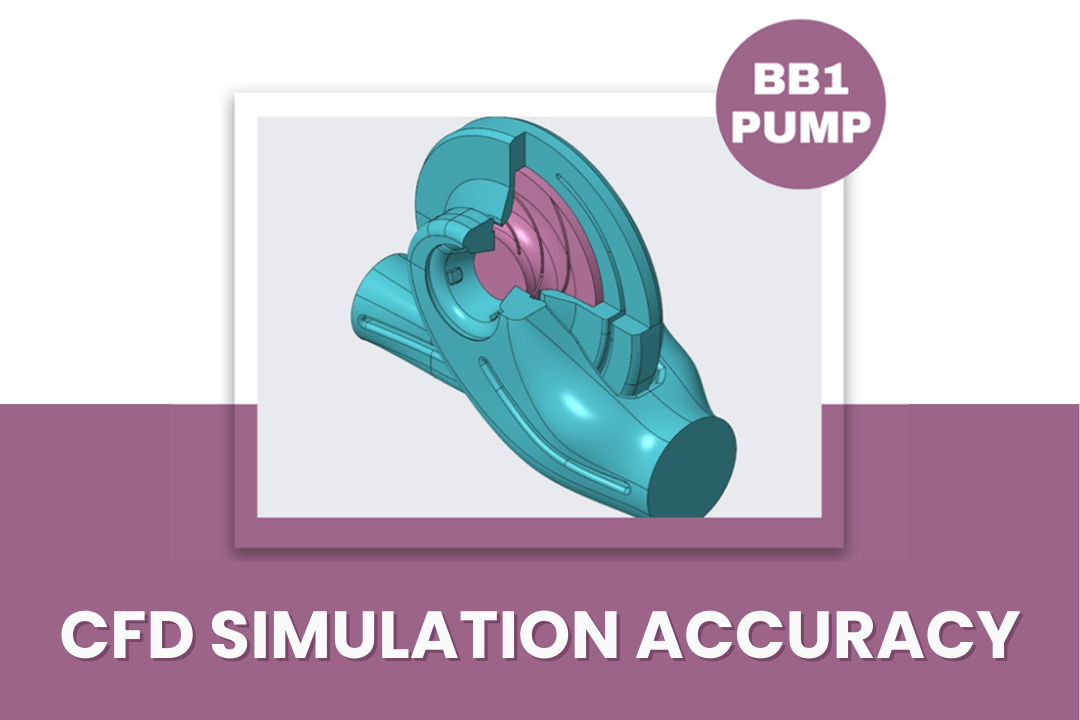

PSS CFD Simulation Accuracy for BB1 Pump

At PSS Group, we continue to push the boundaries of engineering excellence with our precision capabilities in pump performance prediction. A recent project with a BB1 pump highlights how our advanced CFD (Computational Fluid Dynamics) simulation technology accurately predicts performance, providing our customers with reliable and efficient solutions. ### The Challenge […]

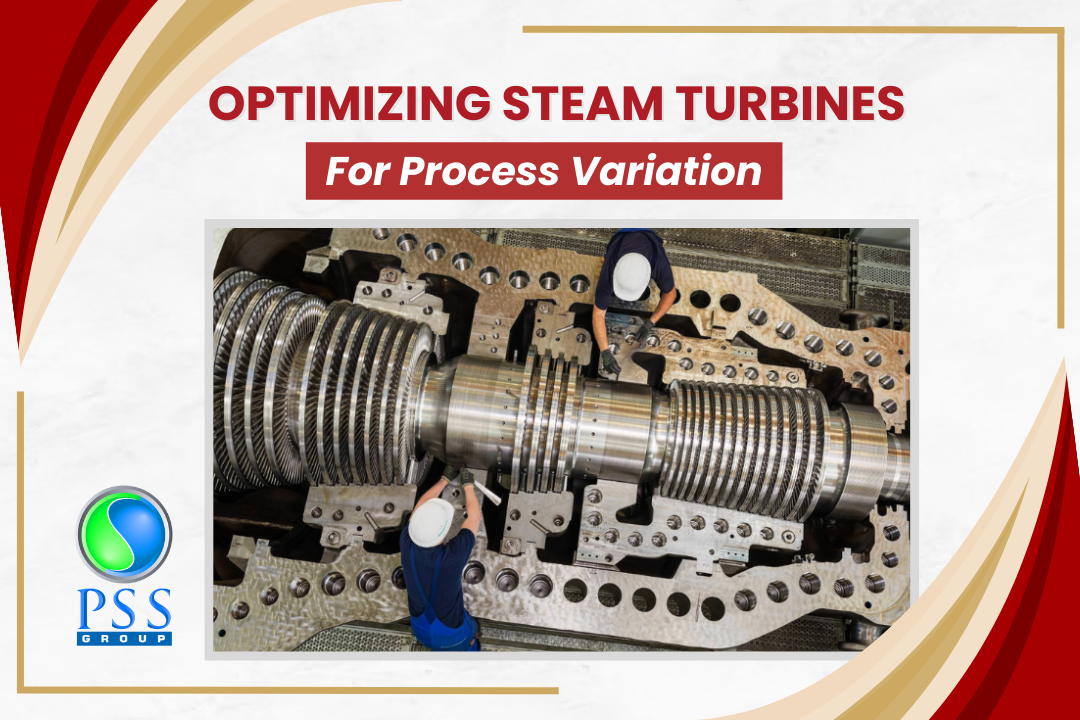

Optimizing Steam Turbines for Process Variation

Power plants face challenges with steam quality, affecting efficiency and equipment lifespan. Biomass plants are particularly impacted due to feedstock variability. In refineries and petrochemical plants, steam quality suffers from carryover, contaminants, and process variability, which reduces steam turbine performance: Erosion and Corrosion: Moisture and contaminants in steam cause turbine blade erosion and corrosion, lowering […]

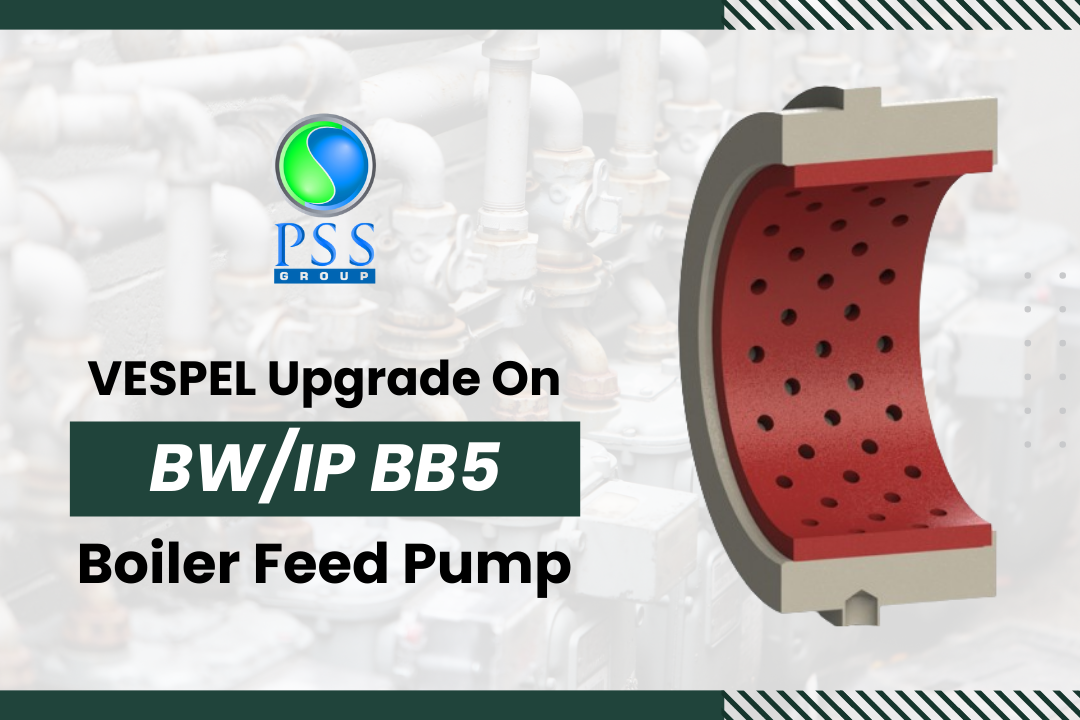

Project Success: Vespel Upgrade on BW/IP BB5 Boiler Feed Pump

PSS Group recently completed a Vespel upgrade on a BW/IP BB5 boiler feed pump driven by a Dresser Rand steam turbine at our Rayong facility. This comprehensive upgrade involved replacing all case rings, center bushing, and throttle bushings on the 9-stage pump. Results at a Glance: Flow Increase: +6% (from 211 to 224 cubic meters/hour) Pump […]

PSS Introduces NFPA 20 Fire Pump Drop-In Upgrades

PSS Introduces NFPA 20 Fire Pump Drop-In Upgrades At PSS, we are excited to announce our latest innovation in fire pump technology: the PSS VS1-11CFP pumps are engineered to meet NFPA 20 criteria. These vertical turbine pumps are designed for optimal performance and durability, incorporating advanced materials and features for enhanced reliability and efficiency. With […]

PSS Milling Techniques for BB3 Split Case Pumps

PSS Milling Techniques for BB3 Split Case Pumps We are excited to share one of our recent projects involving the repair and enhancement of a BB3 Produce Water Pump. Our focus here is on the milling of a concentric serrated flange face finish—a critical process that ensures optimal performance and reliability. This milling was performed […]

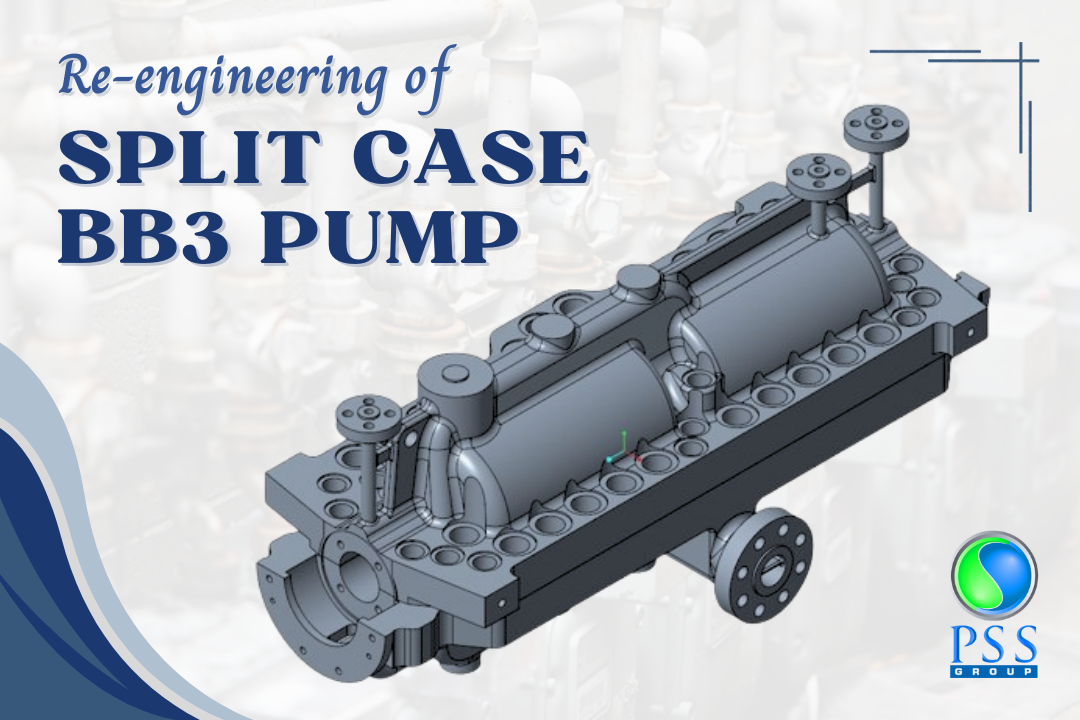

Re-engineering of split case BB3 Pump

Challenges in 3D Modeling of a BB3 Pump PSS recently completed a 3D model of a BB3 pump. In doing this engineering work, we took a multidisciplinary approach by addressing each of the following: **1. Complex Geometries:**BB3 pumps are known for their intricate internal and external geometries. The complex shapes of the impellers, diffusers, and […]

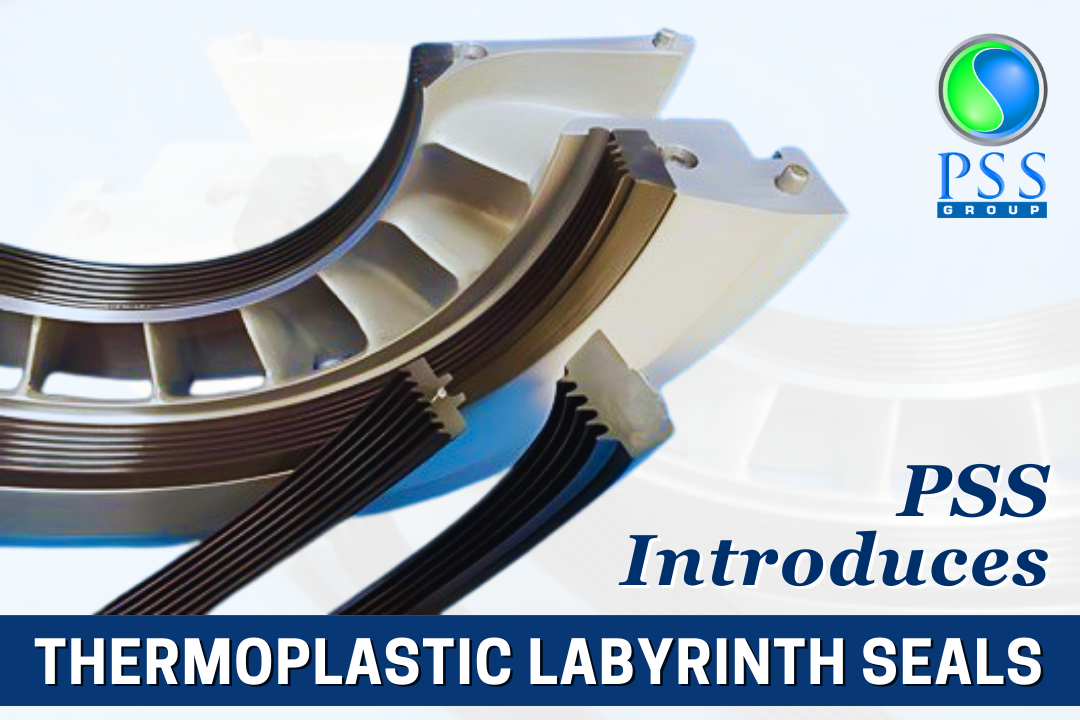

PSS Introduces Thermoplastic Labyrinth Seals

PSS Introduces Thermoplastic Labyrinth Seals We are excited to announce a groundbreaking partnership between PSS and Gulf Coast Bearing and Seal (GCBS) aimed at improving the efficiency and lifetime of turbo compressors in Thailand.. With our commitment to innovation and excellence, we continuously strive to bring you cutting-edge solutions that enhance efficiency and performance. **Introducing […]

PSS Rerates LCO Pump

In a recent milestone achievement, PSS successfully completed the hydraulic rerate of two crucial API pumps at a prominent refinery in Rayong. The endeavor aimed to enhance the head of the German OH2 pump by 20% while maintaining the existing flow conditions. The medium for this operation was Light Cycle Oil (LCO), a byproduct derived […]

PSS Extends Life with Diamond Bearings

Diamond is widely recognized as the hardest known material for unparalleled abrasion resistance. Imagine using these diamonds on bearings and the kind of benefits you can get from this. Through our partnership with US Synthetic and Boulden, PSS supplies polycrystalline diamond (PCD) bearings for the most abrasive process lubricated applications in the industry. We will […]