Blog

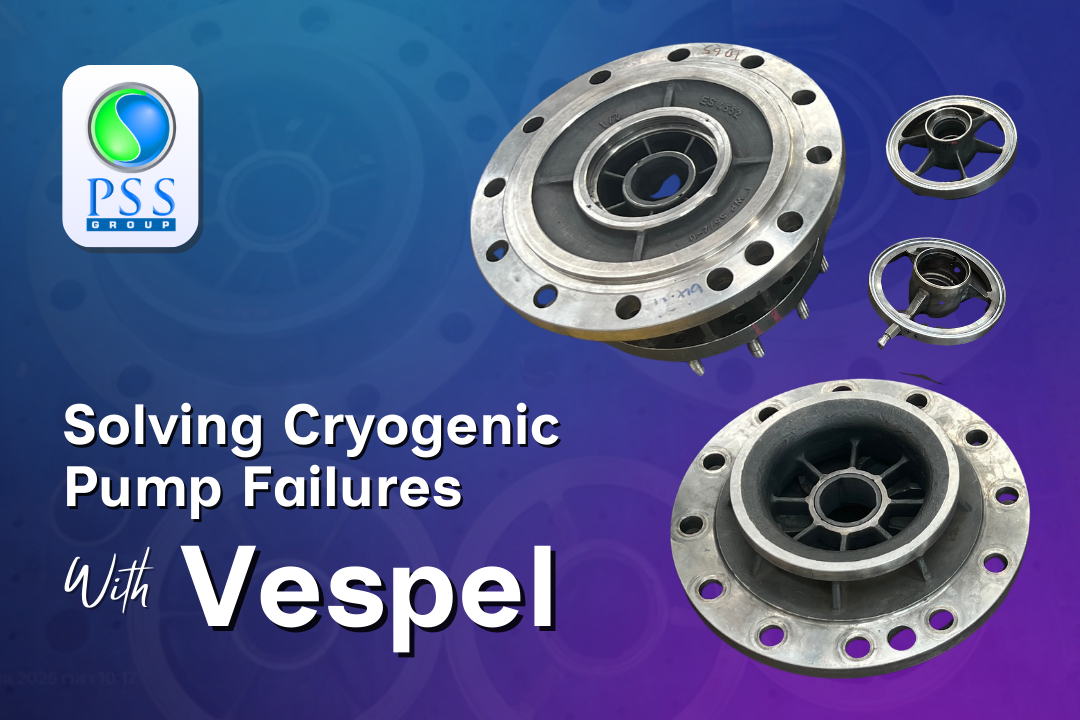

Solving Cryogenic Pump Failures with Vespel

Reliability Spotlight: Solving Cryogenic Failures at a Major Petrochemical Complex

At PSS, we specialize in transforming “problem equipment” into reliable assets. We recently partnered with a major refinery and petrochemical complex to address chronic failures in their Vertical Inline Can (VIC) pump fleet—and the results have redefined their standard for cryogenic operations.

The Challenge: Brittle Failures at -120°C

The facility operates a critical installation of VIC pumps handling cryogenic Ethylene at -120°C. These ultra-low temperature services created a “perfect storm” for mechanical failure:

- Material Fragility: Traditional carbon line shaft bushings were prone to shattering upon contact once the pumps reached cryogenic temperatures.

- Collateral Damage: When a carbon bushing failed, it frequently caused a “domino effect,” destroying spiders, shaft sleeves, and other expensive internal components.

- Poor Lubricity: The process fluid offered negligible lubrication, leading to accelerated wear and high maintenance costs.

The Critical Phase: Surviving the “Cold Start”

One of the most dangerous moments for a cryogenic pump is the cold start. During start-up, pumps often face thermal shock or “flashing” (where the liquid turns to vapor) as the system stabilizes.

Traditional materials are unforgiving during these events. If the pump flashes, carbon bushings can seize or break instantly due to the lack of liquid lubrication. Vespel® CR-6100 changes the game because it can survive dry-running during start-up flashing, protecting the pump until the process flow is fully established.

The Solution: Vespel® CR-6100

To break the cycle of failure, PSS implemented a full upgrade to Vespel® CR-6100 for all shaft and spider bushings. This high-performance composite is engineered to thrive where carbon and metal fail:

- Impact Resistance: Unlike brittle carbon, Vespel® CR-6100 does not shatter. It maintains its physical integrity nearly to absolute zero (-200°C).

- Operational Security: It handles high loads without deformation and features an extremely low coefficient of friction.

- Precision Clearances: It allows for tighter clearances without the risk of seizing, which improves vibration dampening and overall pump efficiency.

Phase 1 Success & Fleet Rollout

The results were immediate. Following the successful performance of the first two upgraded pumps—which have handled the rigors of cryogenic service and cold starts without issue—the facility has made Vespel® CR-6100 their new site standard.

The remaining pumps in the fleet are now scheduled for a systematic upgrade as they come in for planned maintenance. By switching to a material that can survive the transition from ambient to cryogenic temperatures, the plant is achieving:

- Increased Mean Time Between Repair (MTBR)

- Elimination of secondary damage to shafts and spiders

- Lower total cost of ownership

Is Your Equipment Ready for an Upgrade?

If you are managing light hydrocarbon services—such as LPG, Propane, Ethylene, or Propylene—don’t wait for the next expensive failure. PSS maintains a wide range of Vespel® CR-6100 stock sizes ready for immediate shipment to ensure your pumps achieve a longer, more reliable life.