Blog

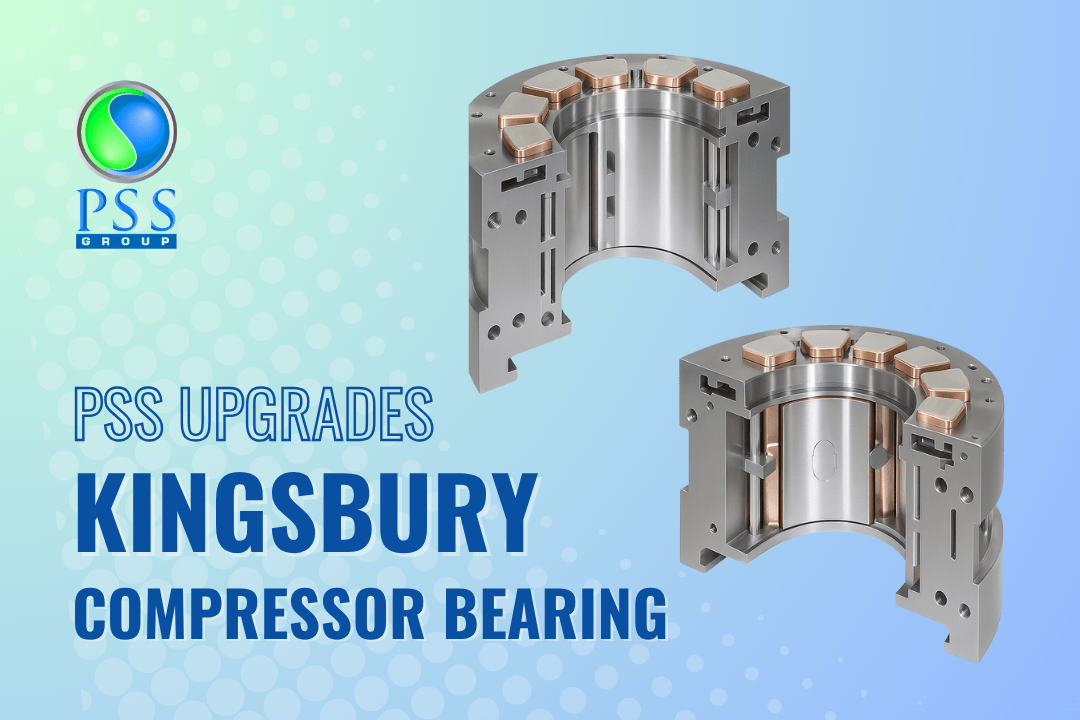

PSS Upgrades Kingsbury Compressor Bearing

PSS Upgrades Kingsbury Compressor Bearing

PSS was recently awarded a job to upgrade a 6” Kingsbury thrust bearing system, significantly improving both thermal performance and temperature monitoring for high-speed rotating equipment.

This project involved replacing the original steel center-pivot pads with copper offset-pivot pads, and upgrading the instrumentation by adding a second temperature sensor to the bearing housing.

Why Copper Pads Were Selected

The decision to switch to copper pads was based on engineering analysis and field experience. Under high-speed operation (up to 14,000 rpm), the original steel pads were approaching their thermal operating limit, with temperatures rising to levels that increase the risk of bearing degradation and reduced service life.

Copper offset-pivot pads offer several advantages:

Lower Operating Temperatures

- Copper has 7 to 10 times higher thermal conductivity than steel.

- This allows faster heat dissipation from the bearing surface.

- Simulations and test data indicate a reduction of 15–25°C in pad temperature under identical conditions.

Improved Load Distribution

- Offset pivot geometry improves hydrodynamic oil film formation.

- This reduces shear and friction while allowing the bearing to carry higher thrust loads more efficiently.

Enhanced Monitoring

- The bearing was upgraded with two temperature sensors to enable improved detection of hot pad zones and thermal imbalance.

- This provides earlier warnings for uneven loading, oil flow reduction, or potential misalignment.

Thermal Study Conducted with GCBS

To support the upgrade, PSS partnered with Gulf Coast Bearing and Seal (GCBS) to perform a comprehensive thermal analysis of the thrust bearing system.

The objective was to compare the predicted temperature performance of steel center-pivot pads versus copper offset-pivot pads across a range of thrust loads. The study assumed the following operating conditions:

- Constant speed of 14,000 rpm

- 6 GPM oil flow to the active thrust bearing

- Thrust load varying from 15% to 100% of rated bearing capacity

Using advanced hydrodynamic modeling software, GCBS calculated pressure distribution and heat generation in the oil film to predict pad temperatures under each load case.

Key outcomes of the analysis:

- At design load (15% of rated), steel pads reached ~80°C, aligning with known design expectations.

- At mid to high loads, steel pad temperatures exceeded 105°C, approaching or exceeding recommended limits.

- Copper pads, under identical conditions, remained well below 100°C, offering a safer operating margin.

This validated the effectiveness of copper pad upgrades for reducing operating temperatures and enhancing bearing durability.

Conclusion

This bearing upgrade is a strong example of how targeted engineering improvements can significantly enhance rotating equipment performance. With lower pad temperatures, improved load capacity, and upgraded instrumentation, the system now offers greater reliability and better long-term monitoring.

PSS remains committed to delivering high-performance solutions for critical rotating equipment—ensuring safer, more efficient, and longer-lasting operation for our customers.