Reliability, Efficiency, and Safety

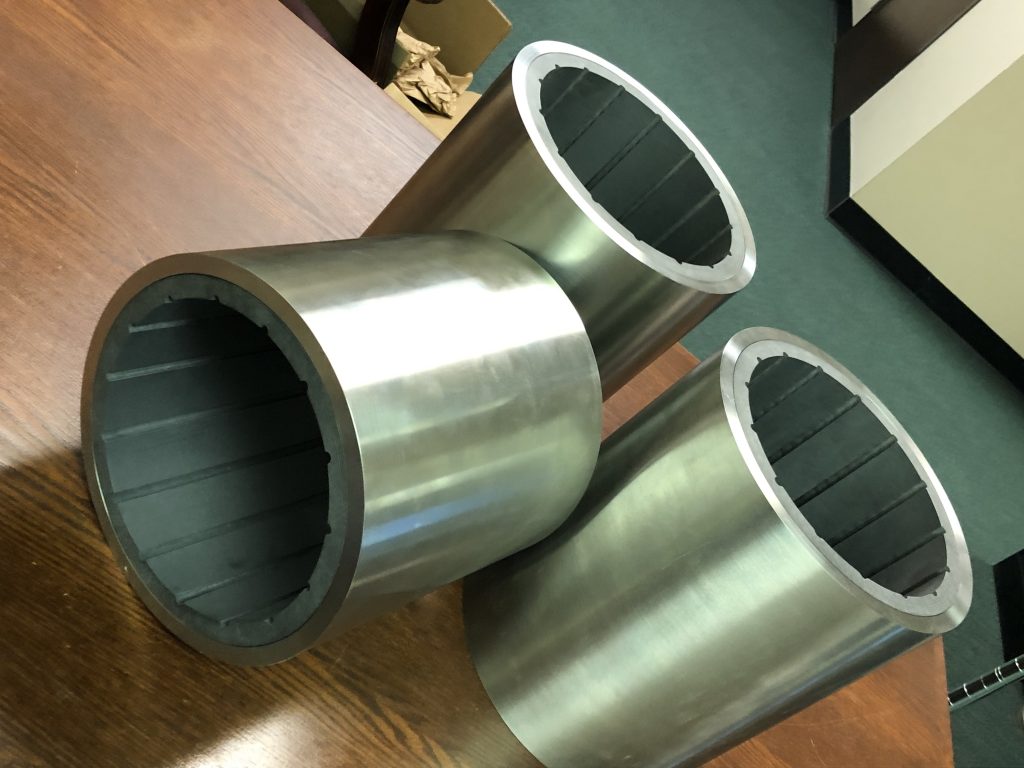

Boulden Wear Materials

We help customers transform the reliability, efficiency, and safety of their rotating and reciprocating equipment by upgrading wear components that were originally designed to optimize first-cost. Our business is uniquely focused on what end-users value most – total cost of ownership – while serving the diverse needs of Original Equipment Manufacturers (OEMs) and Machinery Repair Facilities. Our team brings deep application knowledge, advanced materials expertise, a proven track record of solving complex problems, and innovative thinking to every challenge – always with an intense focus on the customer.

Composite Pump Component Options

- Vespel® CR-6100

- Boulden B-835

- Boulden B-920

- Boulden B-1050

- Metcar M-161

- Metcar M-310

Composite Pump Component Options

- Reduced repair costs—avoid pump seizures

- Easier pump operation—survive dry running

- Lower pump vibration—increased Lomakin Effect

- Lower operating costs—improved pump efficiency

- Improved reliability – longer seal and bearing life

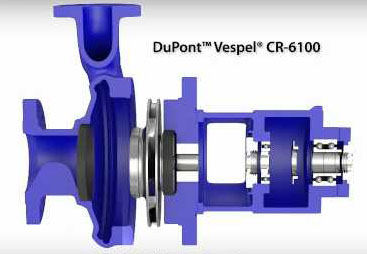

Pumps that break down don’t help you get your job done. Protect your pump from wear, damage and failure with parts made from Dupont™ Vespel® CR-6100.PSS Group carries a large inventory of DuPont™ Vespel® CR-6100 for the rotating equipment market. If you are looking for Vespel® CR-6100, we can ship the material you need today.

What is Vespel® CR-6100?

- Temperature capabilities from cryogenic to 500⁰F (260⁰C)

- Coefficient of thermal expansion less than carbon steel (in the x-y plane)

- Near-universal chemical compatibility. We have not yet found a fluid used in the hydrocarbon processing industry which is chemically incompatible with Vespel® CR-6100.

- Ease of machining and installation

What Types of Parts Can Be Made From Vespel® CR-6100?

What Types of Problems Can Vespel® CR-6100 Parts Solve?