PSS Pump Saves 1 MUSD

This past month, PSS commissioned our first drop in pump – a split case double suction BB1 pump. This was a brilliant success with calculated power savings of about 1 MUSD per year. The drop-in bare pump was fitted into the existing piping envelope with existing baseplate footprints and existing 1 MW motor. There were […]

PSS Overhauls 4 Ebara Compressors

PSS recently overhauled 4 Ebara centrifugal compressors at a major gas processing plant in Thailand. The scope of work included the replacement of the John Crane dry gas seals, couplings, axial and thrust bearings. As the complete overhaul had to be completed within 15 days, PSS deployed 4 different teams for the 4 compressors, utilizing […]

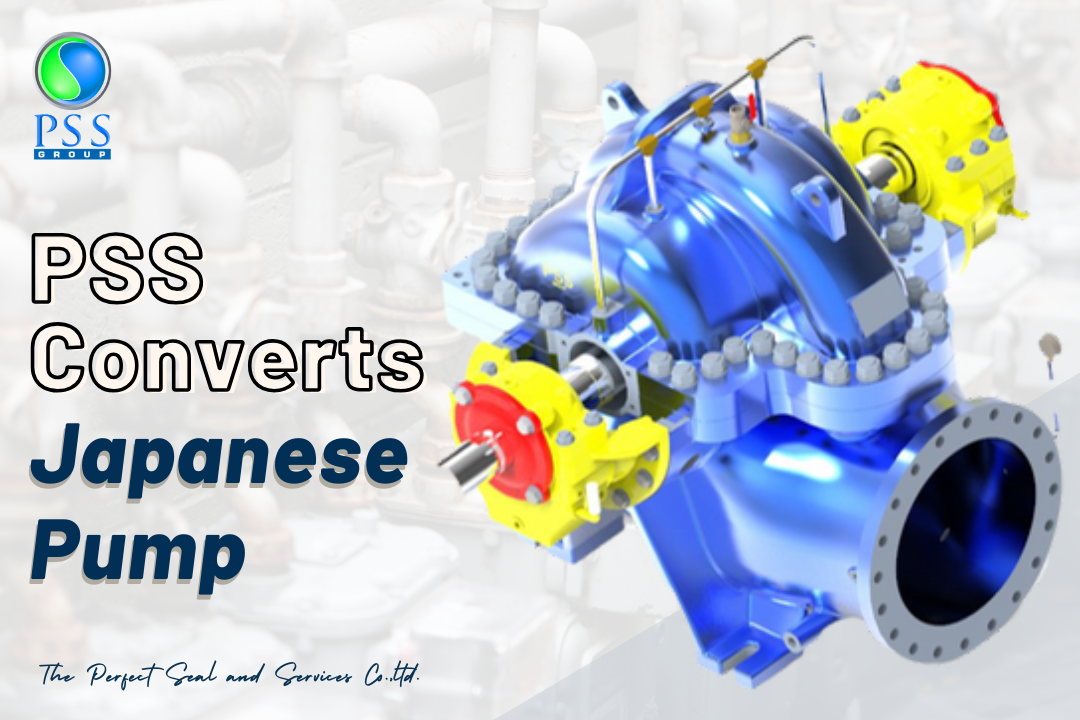

PSS Converts Japanese Pump

A major water utility in Thailand recently awarded a drop-in pump replacement order to PSS. The original pump, a split case BB1 originally manufactured by a major Japanese OEM, suffered a catastrophic failure at site during restart operations. Upon opening the pump in the PSS Pump Repair Center in Rayong, our engineers witnessed severely distorted […]

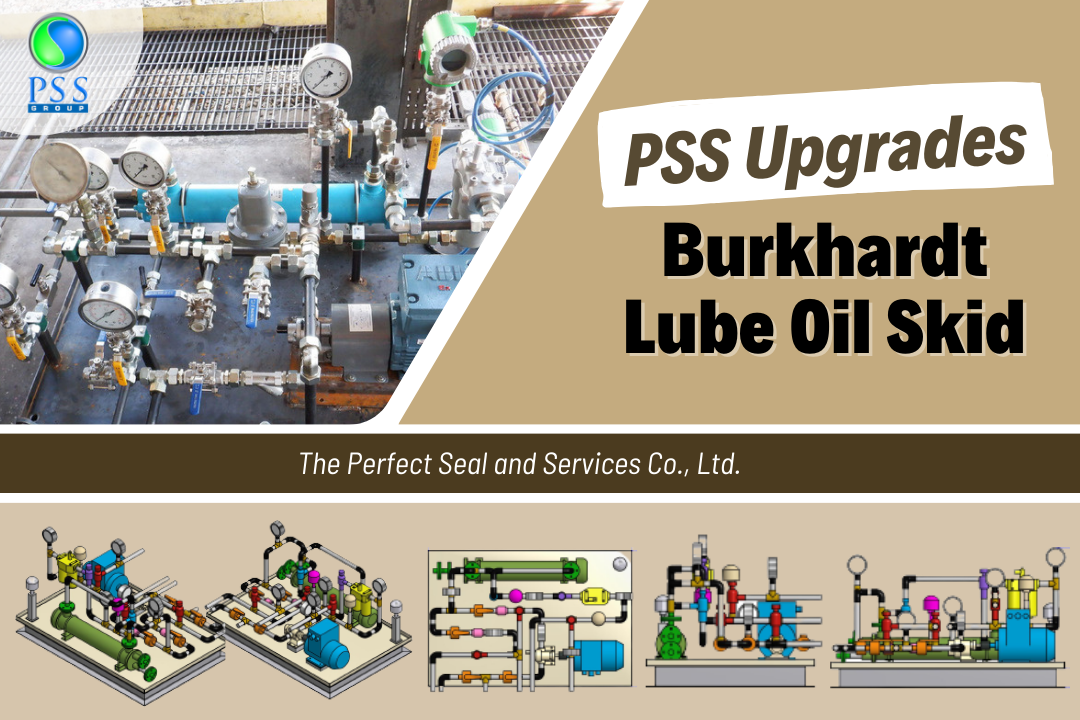

PSS Upgrades Burkhardt Lube Oil Skid

An air products company in Thailand was having reliability issues on their hydrogen process Burkhardt reciprocating compressor due to bearing failures after 2000 hours. The compressor used a splash lubrication system for their main crankshaft bearings. This old Burkhardt unit also did not have any monitoring and protection system for their lubrication system. The maintenance […]

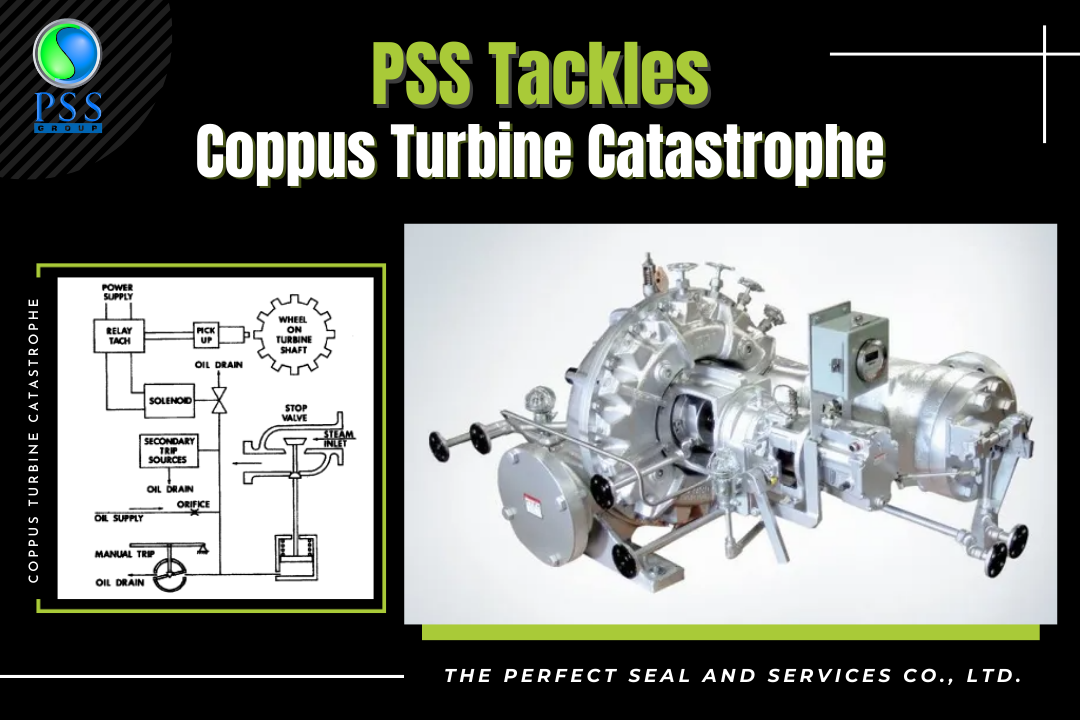

PSS Tackles Coppus Turbine Catastrophe

A major refinery in Thailand had a catastrophic failure on their Dresser Rand Coppus steam turbine RLHB19. The turbine was equipped with an electronic overspeed protection system which was severely damaged – including the main steam turbine shaft, trip pin assembly, multi tooth speed pickup wheel, and the tachometer. PSS did not investigate the root […]

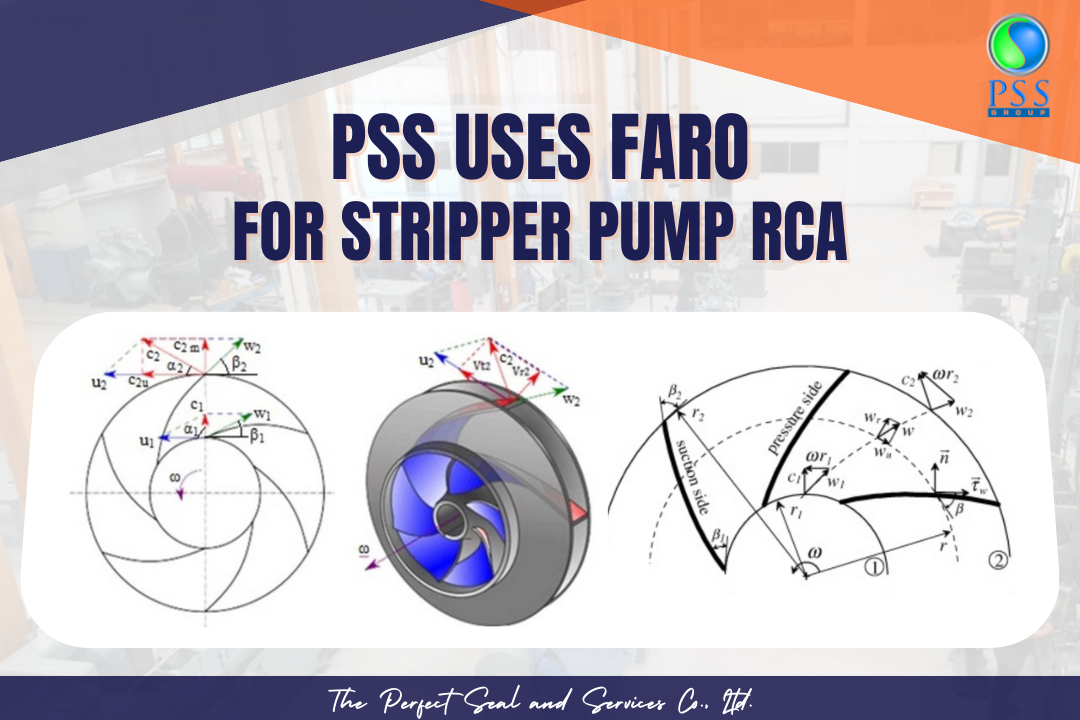

PSS Uses Faro for Stripper Pump RCA

A major refinery in Thailand was having problems operating their Shin Nippon stripper pumps. These are low specific speed single stage OH2 pumps. For this particular process, the customer operates 2 pumps in parallel operation. While operating the pumps, the refinery operators had a problem that while their B pump was operating as per the […]

PSS Solves Flowserve Bad Actor Seal

A synthetic rubber manufacturer was having constant seal leakage problems with their SBR agitator seal for the past 5 years. The Flowserve BRO double seal would leak instantly on the outboard seal while the internal seal would leak inside the agitator after approximately 2 months. Customers incurred massive disruptions in their manufacturing […]

Enecon Tank Seal Solution Passes 5 Year Milestone

A petrochemical plant in Rayong was facing major problems on their storage tanks with corroded annular plates and resulting damaged concrete base. The corrosion was externally created by environmental conditions like rain and the marine environment in Rayong. Rain water accumulation at the base of tanks was a major contributor to the problem. Some commonly […]