PSS Upgrades Metallurgy on BB5 Pump Shaft

We are thrilled to share with you a special accomplishment at PSS – the successful manufacturing of a 2.85 meter BB5 pump shaft with a runout of less than 1 thou or 0.0254 mm, all achieved without any heat bending. What makes this even more special is the use of 17-4 PH material that was […]

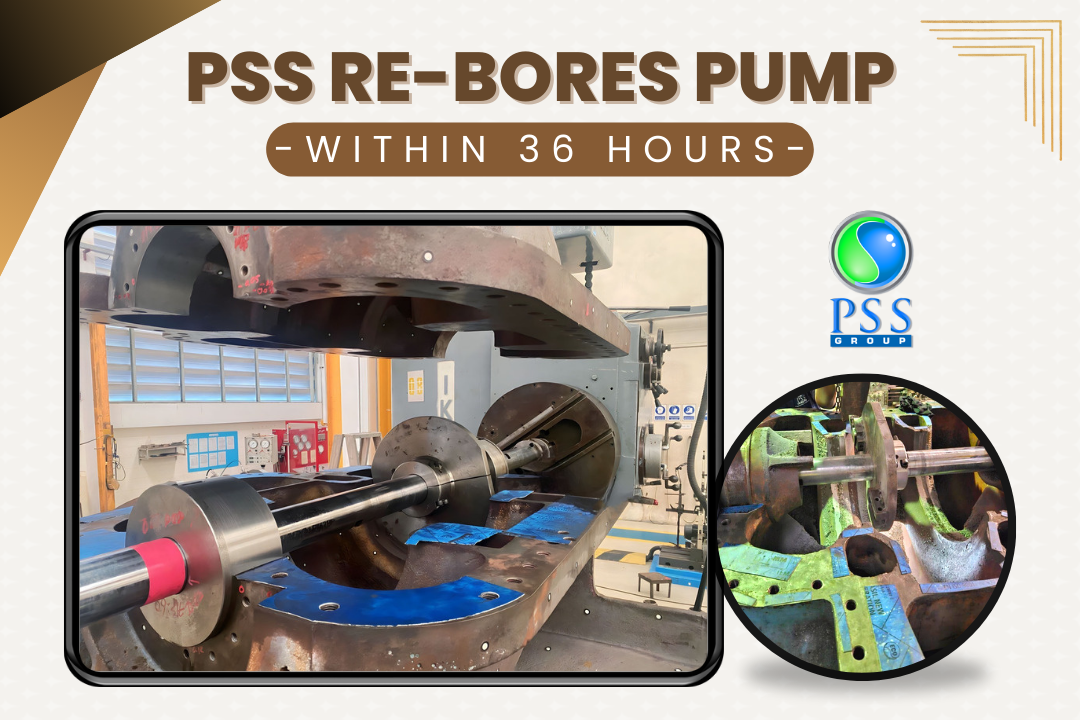

PSS Re-Bores BB1 Pump within 36 Hours

Two weeks back, PSS received a locked-up BB1 pump from one of our major customers along with requests to repair the pump within 24 hours. Our valued customer was facing major problems as they were unable to meet their commitments to their own customers because of this pump and were facing major penalties. The service […]

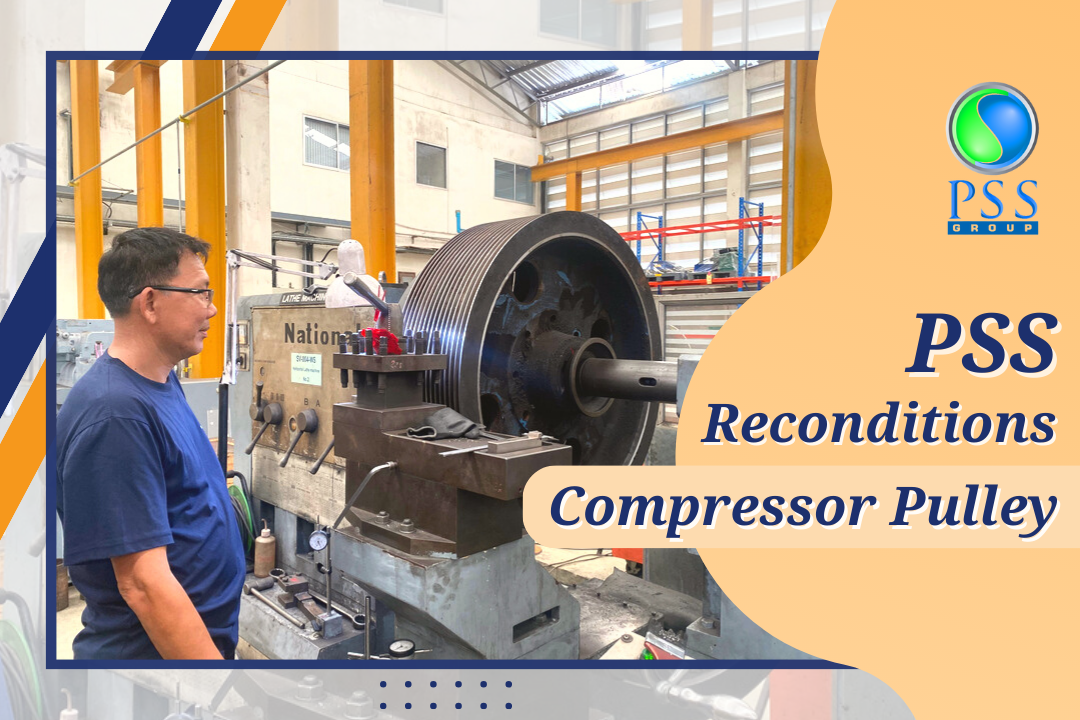

PSS Reconditions Compressor Pulley

In the heart of Thailand’s major refinery, a critical compressor overhaul faced an unexpected hurdle. During the inspection by PSS Workshop, a worn-out and damaged belt groove on the compressor drive pulley was discovered. Customer did not have a spare pulley and asked PSS to find a solution. Our engineers meticulously examined the damaged pulley, […]

PSS Restores 8.3 Meter Sump Pump

We are pleased to share with you the successful completion of a challenging pump restoration project undertaken by PSS at a major refinery in Thailand. Last year, we received a badly corroded VS4 sump pump from the refinery, with a total length of 8.3 meters and a column length below the base plate of approximately […]

Townson Engineers Giant Metallica Expansion Joint

Dear Valued Clients and Partners, We are thrilled to announce a groundbreaking achievement by our subsidiary company, Townson Enterprises. Our engineering team have successfully designed and engineered our largest ever Universal Metallic Expansion Joint, with a diameter of 1.2 meters and a total length of 2.5 meters. The application of this metallic joint is on […]

PSS Introduces Boron Diffusion Service

To deal with erosion and abrasion damage inside pumps, maintenance teams typically go with tungsten carbide or Stellite coating repair solutions. PSS has been offering these services in the market for many years. But now, there is a more superior solution in the market that we would like to introduce. Boron diffusion process creates a […]

PSS Re-Engineers Pump Metallurgy

PSS recently overhauled an unsupported BB1 pump for which we had to supply completely re-designed pump components. The body of the cast iron pump was severely corroded due to galvanic corrosion. The metallurgy of the original pump was a combination of Superior and Inferior materials for the fluid pumped causing accelerated deterioration of the inferior […]

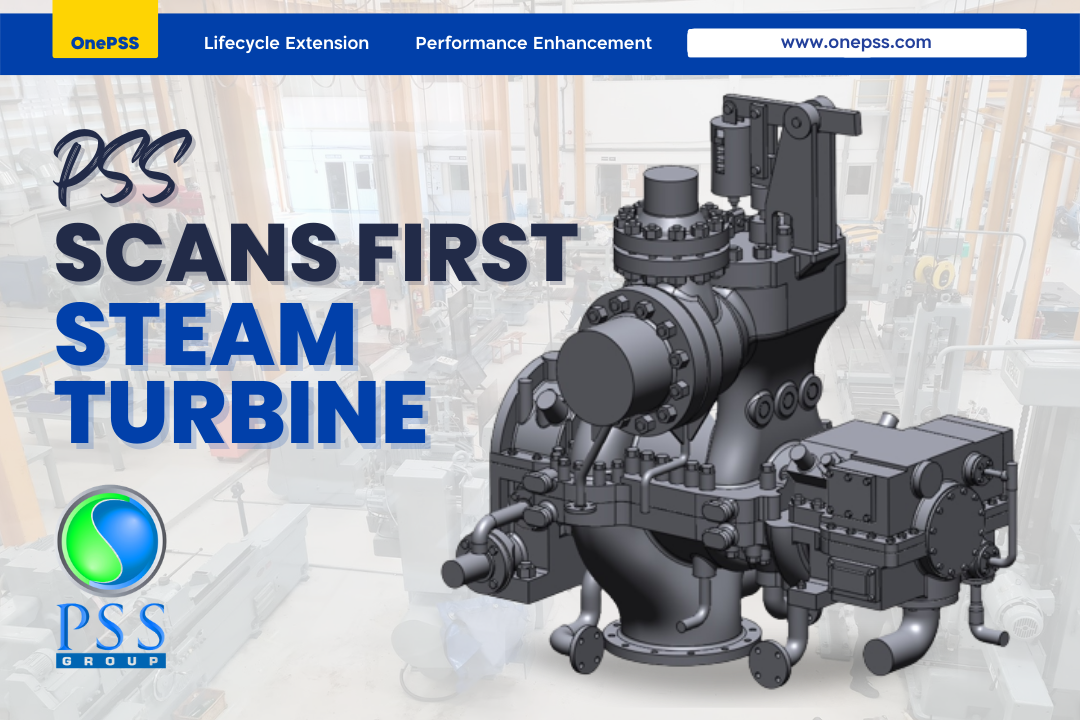

PSS Scans First Steam Turbine

A refinery in Thailand was facing a major dilemma operating their 35 year old recycle gas compressor due to their failing steam turbine driver. The API 612 non condensing steam turbine had a rated output of more than 2 MW. The main steam chest, casing, and exhaust was of A216 WCA construction. […]

PSS Upgrades Vertical Sump Pump

It is possible to more than double a vertical pump’s life by upgrading the pump repair to a “precision remanufacture”. As a result of this, the pump vibration will be reduced and can be verified upon start-up. The precision repair and upgrade cost is usually a small item in the pump’s life cycle cost. This […]

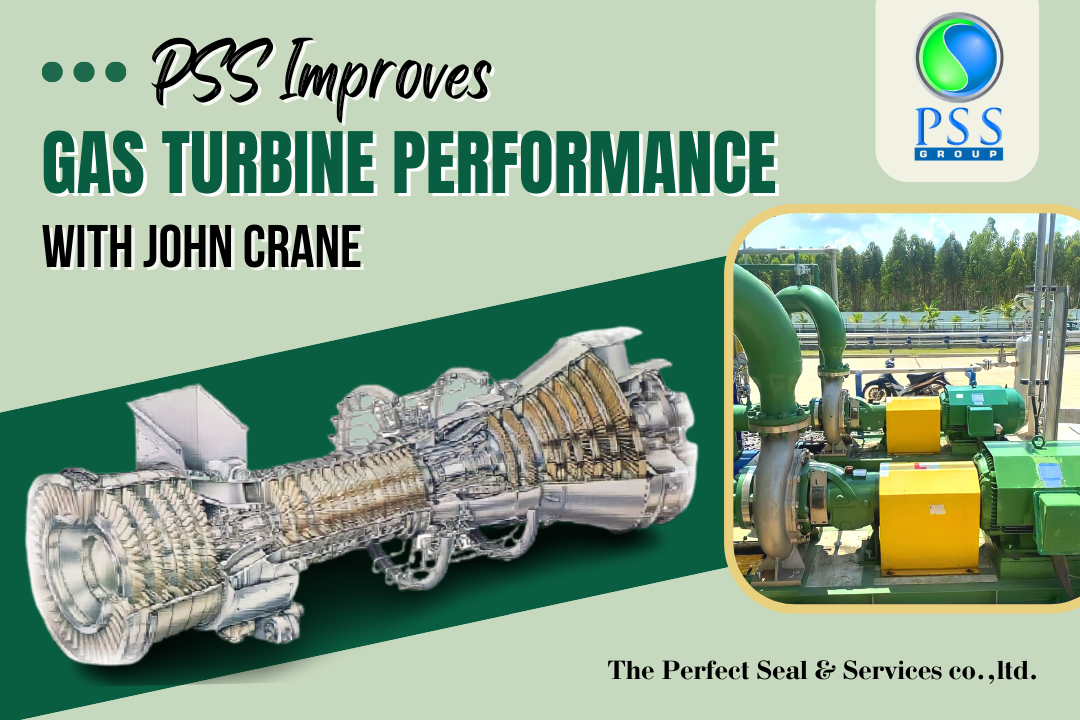

PSS Improves Gas Turbine Performance with John Crane

Heating the air inlet to a gas turbine rather than cooling may appear contrary to what we know about thermodynamic efficiencies. However, the benefits of heating intake air during part-load operation can enhance overall plant flexibility. On a typical gas turbine, output is regulated by adjusting the inlet guide vanes. However, there is a point […]